Hybrid, Wet-Mate, ROV Operable, Electro-Optical Connectors:

As man moves deeper and further offshore to explore the ocean, traditional copper wire does not handle the greater distances with enough bandwidth. It has become imperative to employ fiber optic products to allow the use of the newest technologies that generate considerable amounts of data.

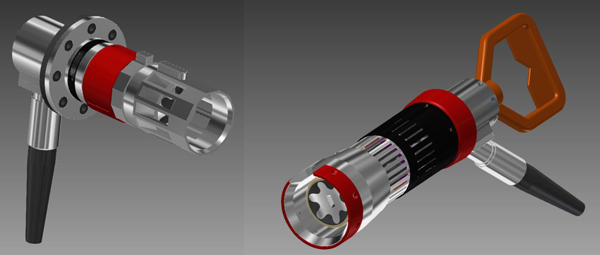

The DEEPLINC Hybrid Optic-Electric DL5500 connection was developed as a result of a recognized need for a high reliability, wet-mateable electric, optic, and hybrid optic-electric connection to support Defense and Offshore Oil & Gas programs. This product is specifically designed to overcome the conventional product shortcomings experienced for more than a decade in these markets. The isolation technology inherent to our product is designed and packaged in an arrangement similar to existing product interfaces, providing a bolt-on reliability enhancement for equivalent cost. The DL5500 further enhances system reliability and eliminates typical connector weak-link failure modes in both Defense Communications and Offshore Oil & Gas applications.

This DEEPLINC connection system solution will allow high volume production because all critical components are manufactured for complete vertical integration. Using a dual chamber “Wet-Mate” connector extends operating life and increases the engagement cycle life of the connector from dozens to hundreds of engagement cycles. This multi-fold extension of the connector’s operating life will represent exceptional savings to customers in any undersea application.

DL5500 PRODUCT FEATURES:

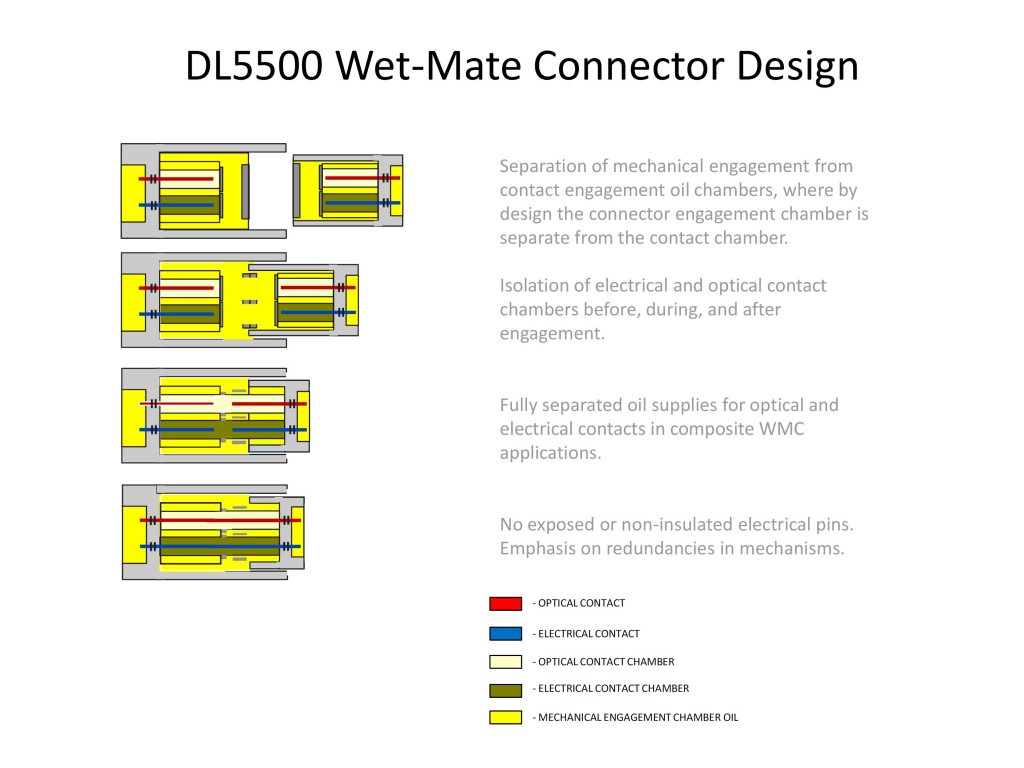

- Full mechanical separation of oil chambers: Mechanical engagement of contacts occurs in fully isolated oil volumes independent of the connector interface engagement oil volumes.

- Barrier isolation of electrical and optical contact chambers before and after engagement.

- Elimination of contact contamination and cross-contamination factors.

- Enhanced life-cycle from increased and separated oil supplies for optical and electrical insert contacts.

- Eliminates exposure of non-insulated plug electrical pins.

- Redundant and robust actuation mechanisms.

- Similar interface and configuration for replacement of existing products.

DESIGN RATINGS:

- Depth Rating: 7,000m (23,000 ft.)

- Design Life: 25 Years

- Operating Temperature: -5ᵒC to +45ᵒC (23ᵒF to 113ᵒF)

- Storage Temperature: -25ᵒC to +60ᵒC (-13ᵒF to 140ᵒF)

- Maximum optical insertion loss of 0.5dB per channel

- Maximum optical back reflection of -45dB per channel

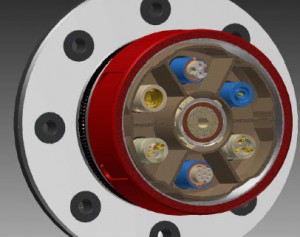

CONTACT TYPES:

| INSERT TYPE | CONTACTS PER INSERT | CONTACT TYPE | TOTAL CONTACT AVAILABILITY

(6 Inserts per Connection) |

CAPACITY |

|---|---|---|---|---|

| Electrical | 3 | 20 Gage | 18 | 600 V |

| Electrical | 2 | 14 Gage | 12 | 1000 V |

| Electrical | 1 | 10 Gage | 6 | 3000 V |

| Electrical | 1 | 14 Gage | 6 | 10 kV DC |

| Optical | 2 | 2.50 mm FC or APC | 12 | 12 Fiber |

| Optical | 8 | 1.25 mm FC or APC | 48 | 48 Fiber |

| Optical | 12-24 SMF | MT Ferrule | 6 | 144 Fiber |

PRINCIPLE OF OPERATION:

The DL5500 Composite connection system assures that critical fiber-to-fiber and electrical-to-electrical contacts are brought together without exposure to external contamination from harsh subsea operating environments. Our product design emphasizes redundancies in actuation mechanisms and uses two oil filled chambers in each connector that provide a patented dual axial barrier in each connector half before, during, and after engagement.